Engineering a cm-scale contractile 3D skeletal muscle actuators for biohybrid robots

Collaborators

PI: Robert Katzschmann

Fellow: Aiste Balciunaite

Collaborators: Edoardo Mazza, Simone Schürle, Lucio Isa, Jess Snedeker

Goal

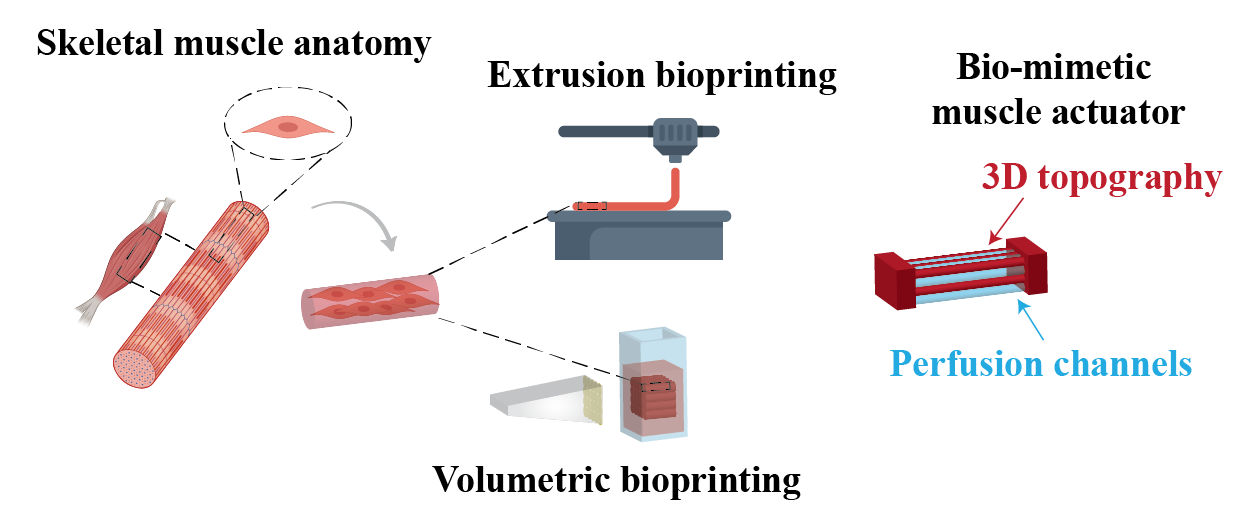

Biological muscles carry the promise of being energy efficient and soft actuators for next generation robots, provided we can engineer contractile skeletal muscle constructs and integrate them into a robotic skeleton. Contractile skeletal muscle constructs also hold great potential in the field of medical implants and prosthesis. However, we are currently limited in our ability to engineer contractile skeletal muscle constructs past the mm-scale, mainly due to the challenges of nutrient perfusion and lack of ability to recapitulate the necessary biological and mechanical features of the native muscle extracellular matrix using available biofabrication techniques. In this project, we aim to innovate on current biofabrication methods in order to engineer a cm-scale skeletal muscle tissue for actuating a bio-hybrid robot, capable of a higher force generation than current state-of-the-art skeletal muscle actuators.

Methodology

Current state-of-the-art examples of biohybrid robots actuated by tissue engineered muscle all rely on a molding method or single cell layers to fabricate the muscle construct. Advantageously, such techniques allow for the use of biologically relevant matrix materials that contain the necessary signaling factors to allow proper differentiation of myoblasts into contractile myofibers. Mechanical tension or electrical stimulation during the differentiation process are used to help guide the skeletal muscle cells towards a contractile phenotype. However, molding and single cell layers are inherently limited in their ability to generate larger 3D constructs: cell layers lack 3D geometry, and molding cannot replicate the topography or vasculature of skeletal muscle. Therefore, we aim to adapt techniques such as extrusion bioprinting or volumetric printing to the fabrication of skeletal muscle constructs by innovating on the materials and strategies used to fabricate and then properly differentiate the construct towards a high force generating and contractile phenotype. Finally, we will integrate the skeletal muscle constructs to a skeleton for our biohybrid robot.